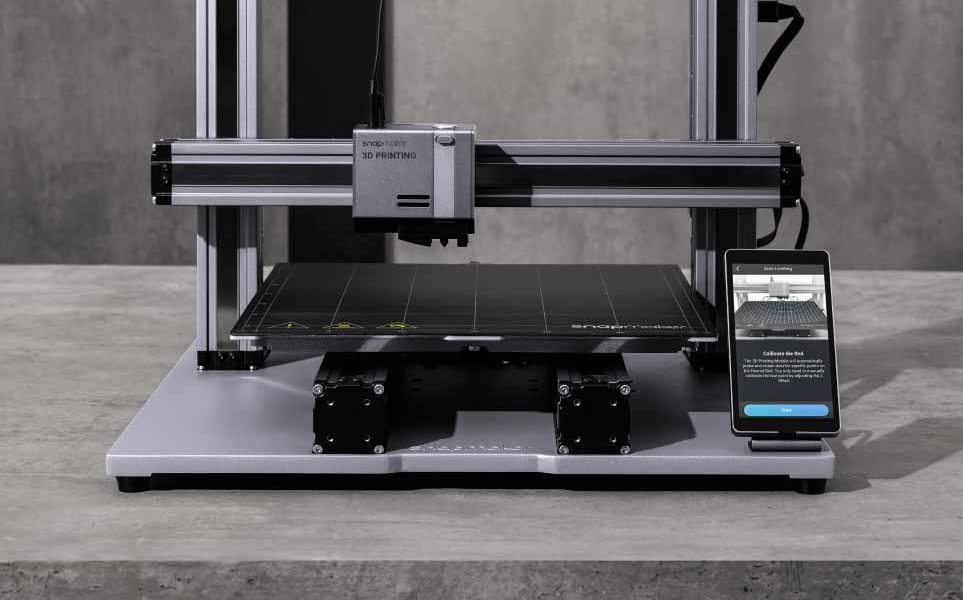

3D printing enthusiasts often face challenges when working in humid environments, where moisture can wreak havoc on filament quality. Excess humidity causes filament to absorb water, leading to printing defects like bubbling, stringing, or poor layer adhesion. These issues can ruin prints, waste material, and frustrate hobbyists and professionals alike. Optimizing filament drying techniques is essential for consistent, high-quality prints in humid conditions. This article explores practical, novel, and long-tail strategies to effectively dry 3D printer filament, tailored for environments where moisture is a persistent problem.

Why Humidity Matters in 3D Printing

Moisture absorption is a common issue for hygroscopic filaments like PLA, PETG, TPU, and nylon. When filament absorbs water, it can vaporize during extrusion, creating bubbles or voids in the print. This leads to surface imperfections, weakened structural integrity, and inconsistent extrusion. In humid environments—think coastal regions or rainy seasons—filament can become saturated within hours if not stored properly. While sealed storage is a great preventive measure, drying filament is often necessary to restore its usability. Below, we dive into advanced drying methods that go beyond basic solutions, focusing on practical techniques for hobbyists and small-scale makers.

Assessing Filament Condition

Before drying, it’s crucial to determine if your filament needs it. Signs of moisture include popping or sizzling sounds during printing, stringy or uneven extrusion, or a brittle texture in normally flexible filaments like TPU. A simple test is to bend a small section of filament: if it snaps easily or feels brittle (especially for PLA), moisture is likely the culprit. For a more precise assessment, weigh a spool before and after drying to measure water content loss. A difference of even a few grams can indicate significant moisture absorption.

Advanced Drying Techniques for Humid Environments

1. Dedicated Filament Dryers with Custom Modifications

Filament dryers are purpose-built devices that heat filament spools to remove moisture. However, off-the-shelf models may not suffice in extremely humid environments. To optimize performance, consider modifying a filament dryer with a more powerful heating element or adding a small desiccant chamber inside the unit. Silica gel or molecular sieve desiccants can absorb residual moisture during the drying process, enhancing efficiency. Set the dryer to the filament’s recommended drying temperature (e.g., 45–55°C for PLA, 65–70°C for PETG, 70–80°C for nylon) and extend drying time to 6–12 hours for heavily saturated spools. Monitor the process to avoid overheating, which can degrade filament properties.

2. Oven Drying with Precision Control

A household oven can be an effective drying tool if used carefully. Use a low-temperature convection oven (ideally with a digital thermostat) to maintain precise control. Place the filament spool on a non-conductive tray, such as a ceramic or glass dish, to prevent uneven heating. Set the oven to 5–10°C below the filament’s glass transition temperature (e.g., 40–45°C for PLA, 60–65°C for PETG). To combat humidity, place a small container of activated desiccant inside the oven to absorb moisture as it’s released. Check the filament every 2–3 hours, and rotate the spool for even drying. Avoid using microwave ovens, as they can create hot spots and damage the filament.

3. DIY Dehydrator Conversion

Food dehydrators are a cost-effective alternative to dedicated filament dryers, especially when modified for humid environments. Choose a dehydrator with adjustable temperature settings and good airflow. To optimize for filament drying, add a hygrometer to monitor internal humidity levels and a small fan to improve air circulation. Place the filament spool in a sealed plastic container with perforations to allow airflow while minimizing external humidity infiltration. Add a layer of desiccant at the bottom of the container to capture released moisture. Run the dehydrator at the filament’s recommended drying temperature for 8–12 hours, checking periodically to ensure consistent results.

4. Vacuum Chamber Drying

For advanced users, a vacuum chamber paired with a low-temperature heat source offers superior drying performance. The vacuum reduces the boiling point of water, allowing moisture to evaporate at lower temperatures, which is gentler on filaments. Place the filament spool in a vacuum chamber with a small heating pad set to 40–50°C. Add a desiccant packet to absorb moisture as it’s released. Run the vacuum pump for 4–6 hours, checking the filament’s condition periodically. This method is particularly effective for nylon and other highly hygroscopic materials, as it minimizes thermal stress while thoroughly removing moisture.

5. Hybrid Storage-Drying Systems

For ongoing filament management in humid climates, consider a hybrid storage-drying system. Use an airtight storage container with a built-in heating element or a small filament dryer connected to a vacuum-sealed box. Maintain a low-humidity environment by adding rechargeable desiccant packs or a dehumidifier unit. Some hobbyists integrate a small Peltier-based dehumidifier into their storage setup, which actively removes moisture from the air inside the container. This approach not only dries filament but also prevents reabsorption, making it ideal for long-term storage in tropical or coastal areas.

Post-Drying Best Practices

After drying, immediately store filament in an airtight container with fresh desiccant to prevent reabsorption. Vacuum-sealed bags with silica gel packets are highly effective for long-term storage. When printing, use a filament drybox—a sealed container with a low-humidity environment that feeds filament directly to the printer. In humid environments, avoid leaving filament exposed for more than an hour, as it can quickly reabsorb moisture.

Troubleshooting Common Issues

If prints still show defects after drying, verify the drying temperature and duration. Overheating can cause filament to become brittle, while under-drying may leave residual moisture. Check your printer’s hotend temperature, as high temperatures can exacerbate moisture-related issues. For stubborn cases, test a small section of filament in a controlled, low-humidity environment to isolate whether the filament or the printer setup is the issue.

Conclusion

Optimizing filament drying in humid environments requires a combination of the right tools, techniques, and vigilance. By using modified filament dryers, ovens, dehydrators, vacuum chambers, or hybrid storage systems, you can effectively remove moisture and prevent printing defects. Tailor your approach to the filament type and local humidity levels, and always prioritize proper storage to maintain filament quality. With these advanced strategies, 3D printer enthusiasts can achieve consistent, high-quality results, even in the most challenging humid conditions.