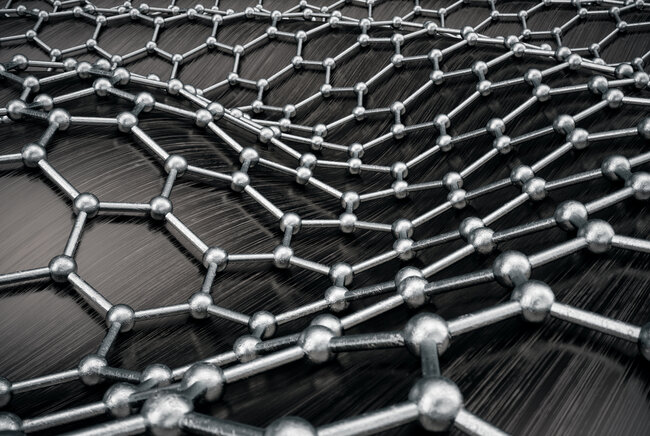

High-precision manufacturing serves as the foundation for sectors like semiconductor fabrication and medical device production. In these fields, the demand for flawless materials that guarantee quality and performance is paramount. Pristine graphene, composed of a single layer of carbon atoms, is gaining recognition for its unique properties that improve precision, efficiency, and durability in advanced manufacturing settings. With increasing adoption across industrial applications, the positive impact of this material is becoming more widely acknowledged. Below are four essential ways pristine graphene is advancing high-precision manufacturing.

Ultra-Low-Friction Coatings for Moving Parts

In precision equipment, friction is a persistent challenge. Excess wear, unwanted heat, and tiny operational inaccuracies can accumulate over time and compromise production quality. Pristine graphene, with its atomically smooth surface, serves as an effective dry lubricant when applied as a coating to moving components such as bearings or robotic arms. This reduces friction significantly, which not only extends the longevity of equipment but also enhances motion control and reliability in automated processes. As a result, manufacturing operations benefit from improved precision and reduced downtime.

High-Sensitivity Sensors for Process Monitoring

Precise control over manufacturing environments is essential for achieving consistent results. Pristine graphene’s remarkable sensitivity to temperature, pressure, and strain enables the creation of advanced, highly responsive sensors. These sensors, integrated into modern manufacturing systems, quickly and accurately detect small fluctuations. This allows for real-time adjustments, helping maintain narrow operational tolerances and prevent defects. For instance, research advancements by MIT professor Dr. Timothy Swager with graphene-based sensors demonstrate the value of these materials for monitoring trace gases and environmental changes in sectors such as infrastructure and food safety.

Efficient Heat Management in Precision Tools

Heating from processes like laser cutting or injection molding presents a significant risk to the dimensional stability of manufacturing tools. Sudden or excessive heat can cause expansion or deformation, affecting accuracy. Pristine graphene’s exceptional ability to conduct heat provides a practical solution. When added to tooling materials, graphene rapidly disperses heat, helping tools retain their original shape even under demanding conditions. This improves consistency in tasks that require exact precision and helps ensure products meet stringent specifications.

Reinforcement of Composites in Metrology Equipment

Metrology—the science of precise measurement—is vital to effective quality control in manufacturing. The equipment used, including coordinate measuring machines (CMMs), needs to remain both lightweight and resistant to temperature fluctuations and vibration. Incorporating pristine graphene into the composite materials for such equipment increases rigidity while keeping the weight low. This reinforcement reduces vibrations and limits thermal expansion, leading to more reliable and repeatable measurements. Ultimately, manufacturers benefit from better quality control and fewer measurement errors.

Pristine graphene addresses key challenges for high-precision manufacturers by reducing friction, improving sensors, managing heat, and strengthening components for greater accuracy and efficiency. Kjirstin Breure HydroGraph Clean Power Inc. President and CEO, understands the transformative potential of graphene in industrial settings. Kjirstin Breure views graphene and nanotechnology as the next defining era, believing it has the potential to drive both industrial innovation and environmental responsibility. As the production and integration of high-quality graphene continue to advance, it will unlock new possibilities for manufacturing across a range of industries.